Metals (stainless steel, aluminum...)

Stainless steel and aluminum objects and components.

Gallery (all photos 70) :

Aluminum battens before bead blasting…

Aluminum battens before bead blasting… Aluminum battens after bead blasting.

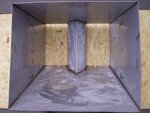

Aluminum battens after bead blasting. Stainless furnace inner housing corroded with titanium-nitride and aluminum-nitride. (1)

Stainless furnace inner housing corroded with titanium-nitride and aluminum-nitride. (1) Stainless furnace inner housing after blasting. (2)

Stainless furnace inner housing after blasting. (2) Aluminum cast before homogenization. Removing the polishing marks. (1)

Aluminum cast before homogenization. Removing the polishing marks. (1) Aluminum cast after bead blasting. You can observe that the homogenized surface and the screw-thread are intact. (2)

Aluminum cast after bead blasting. You can observe that the homogenized surface and the screw-thread are intact. (2) A homogenized aluminum cast after black eloxal process (Philips X-ray machine component) (3)

A homogenized aluminum cast after black eloxal process (Philips X-ray machine component) (3) Stainless object before working… (1)

Stainless object before working… (1) Stainless object after beading… (2)

Stainless object after beading… (2) The other side of the stainless object (3)

The other side of the stainless object (3) Stainless object safety-packed for delivery. (4)

Stainless object safety-packed for delivery. (4) Pasta machine before degreasing and beading. (1)

Pasta machine before degreasing and beading. (1) Pasta machine before degreasing and beading. (2)

Pasta machine before degreasing and beading. (2) Pasta machine before degreasing and beading. (3)

Pasta machine before degreasing and beading. (3) Pasta machine before degreasing and beading. (4)

Pasta machine before degreasing and beading. (4) After degreasing and soaking, the object can be blasted. (1)

After degreasing and soaking, the object can be blasted. (1) After degreasing and soaking, the object can be blasted. (2)

After degreasing and soaking, the object can be blasted. (2) After degreasing and soaking, the object can be blasted. (3)

After degreasing and soaking, the object can be blasted. (3) After degreasing and soaking, the object can be blasted. (4)

After degreasing and soaking, the object can be blasted. (4) Soaked and beaded. Now it can be installed. (1)

Soaked and beaded. Now it can be installed. (1) Soaked and beaded. Now it can be installed. (2)

Soaked and beaded. Now it can be installed. (2) Soaked and beaded. Now it can be installed. (3)

Soaked and beaded. Now it can be installed. (3) The mount of a banking entry system after welding. (1)

The mount of a banking entry system after welding. (1) The mount of a banking entry system after welding. (2)

The mount of a banking entry system after welding. (2) The mount of a banking entry system after beading. (1)

The mount of a banking entry system after beading. (1) The mount of a banking entry system after beading. (2)

The mount of a banking entry system after beading. (2) Red copper electrical component after being welded with silver.

Red copper electrical component after being welded with silver. Electrical component blasted with fine material ensuring perfect electrical contact…and it’s aesthetical.

Electrical component blasted with fine material ensuring perfect electrical contact…and it’s aesthetical. Feeding hopper for a food machine. (1)

Feeding hopper for a food machine. (1) Feeding hopper for a food machine. (2)

Feeding hopper for a food machine. (2) Feeding hopper for a food machine. (3)

Feeding hopper for a food machine. (3) The feeding hopper preserved with beading and oiling.(1)

The feeding hopper preserved with beading and oiling.(1) The feeding hopper preserved with beading and oiling.(2)

The feeding hopper preserved with beading and oiling.(2) The feeding hopper preserved with beading and oiling.(3)

The feeding hopper preserved with beading and oiling.(3) Stainless steel machine component after beading.

Stainless steel machine component after beading. Tempered stainless pump component.

Tempered stainless pump component. Tempered stainless pump component after cleaning.

Tempered stainless pump component after cleaning. The housing of a slot machine made in 1914, before blasting.

The housing of a slot machine made in 1914, before blasting. The housing of a slot machine made in 1914, after blasting.

The housing of a slot machine made in 1914, after blasting. The tanks of a stainless furnace.

The tanks of a stainless furnace. The mounts of stainless furnace tanks.

The mounts of stainless furnace tanks. Workpieces of Military History Museum before machining.

Workpieces of Military History Museum before machining. Workpieces of Military History Museum after machining.

Workpieces of Military History Museum after machining. Old water meters before bead blasting.

Old water meters before bead blasting. Old water meters before bead blasting.

Old water meters before bead blasting. Old water meters after bead blasting.

Old water meters after bead blasting. Brass model sandblasted with pearls.

Brass model sandblasted with pearls. Sewer drain lid cleaned.

Sewer drain lid cleaned. Stainless steel hood before sandblasting.

Stainless steel hood before sandblasting. Stainless steel hood after sandblasting.

Stainless steel hood after sandblasting. Stainless steel container before sandblasting.

Stainless steel container before sandblasting. Stainless steel container after beating.

Stainless steel container after beating. Cleaning a copper plate.

Cleaning a copper plate. Gate of Access cover.

Gate of Access cover. Sewing of industrial washing machines with stainless steel foam...

Sewing of industrial washing machines with stainless steel foam... Sewing of industrial washing machines with stainless steel foam...

Sewing of industrial washing machines with stainless steel foam... Industrial washing machine prepared for sandblasting, pickled.

Industrial washing machine prepared for sandblasting, pickled. Sandblasting of finishing elements for industrial washing machine, preparation for painting.

Sandblasting of finishing elements for industrial washing machine, preparation for painting. Sandblasted tank with pearls.

Sandblasted tank with pearls. Mc Donald's shop equipment made of stainless steel.

Mc Donald's shop equipment made of stainless steel. Plaque of Liberty Bridge before sandblasting.

Plaque of Liberty Bridge before sandblasting. Plaque of Liberty Bridge after sandblasting.

Plaque of Liberty Bridge after sandblasting. Watch Beaded.

Watch Beaded. Bronze propeller.

Bronze propeller. Stainless steel tank with sand blasting.

Stainless steel tank with sand blasting. Stainless steel container packed.

Stainless steel container packed. Aluminum optical instrument is a fine bead spraying.

Aluminum optical instrument is a fine bead spraying. Stainless steel container roughly beaded.

Stainless steel container roughly beaded. Stainless steel container with bead sprouts.

Stainless steel container with bead sprouts. Brass Blower (Matthias Church).

Brass Blower (Matthias Church).

Gallery (all photos 70) :

Every now and then we update our gallery with interesting, inventive or spectacular photos.